Supply and Demand Waves in CNC-Manufacturing

In the manufacturing industry, we have spent the last few years moving from crisis to crisis. Corona caused quite a disturbance regarding our customer and supplier relationships. And just as supply returned to normal, the Ukraine war tore everything apart again. Energy is at a rocket cost, interest rates are rising and over-indebted suppliers are threatened with insolvency. No wonder everyone has been talking about resilience in recent months. Good to know there is a solution for all of this in manufacturing.

If you think a little beyond the short-term trend, the economic principle of supply and demand waves will help: In times of high demand, companies invest more in order to get a piece of the pie. No wonder that machines and personnel are currently hard to come by. Those who could, have stocked up on both. Those who are still looking, are going to wait a long time. But as the availability of goods increases with the investments materialising, supply will eventually take over again. The seller’s market will turn into a buyer’s market, where buyers will have the power to negotiate again.

In short, after the demand boom, there will be an oversupply of many goods. The result will be high cost pressure across industries to be competitive in times of oversupply. The waves of demand and supply are currently moving at a faster frequency than ever before. Especially in the manufacturing industry, the transition from a demand-driven and buyer-resilient to a price-sensitive supplier structure is challenging.

Digital Platform-Technology for Adaptability

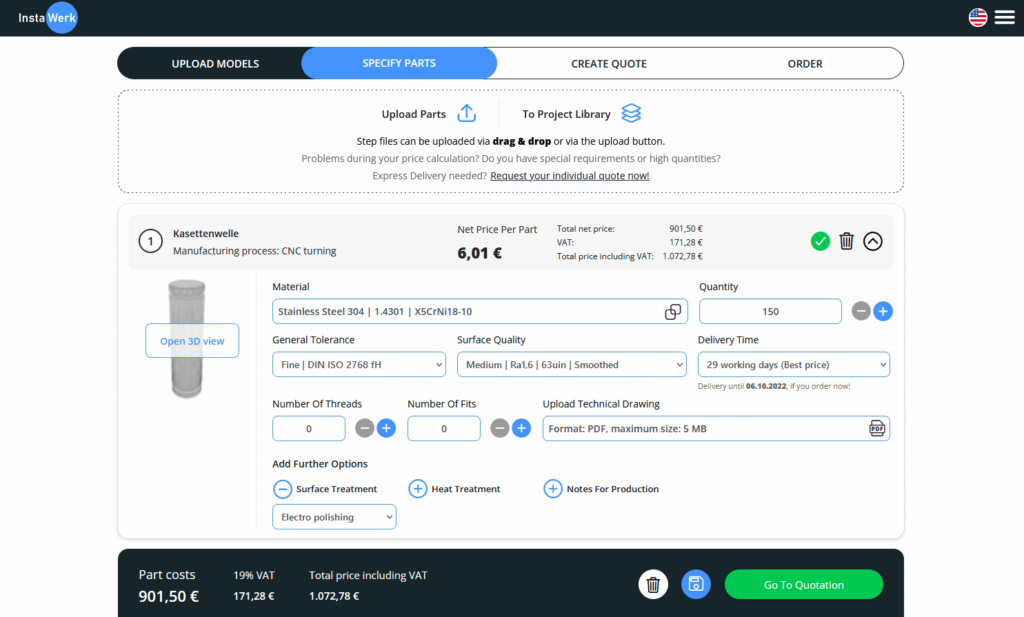

To master the transition, adaptability is key. One way buyers can meet this changing demand for availability and competitive terms is through manufacturing platforms like InstaWerk. As a digital provider of manufacturing parts, we mediate the production of individual components with digital competence. By using manufacturing networks of international companies and thousands of machines, we offer unbeatable availability as a CNC platform.

The principle is similar to the use of funds or ETFs in the financial market. Instead of betting on individual (supposedly superior) stocks or suppliers, the risk is minimized by spreading the risk over many suppliers in our exclusive network. In addition, fallback options are always available in the network, which increases availability and crisis resistance.

Bundling orders also gives us a decisive cost advantage over individual purchasing as a single company. As a platform, we can negotiate better conditions for our customers and realize quality based on established relationships. This is facilitated through relevant order volumes.

Quality remains the decisive argument for us. CNC components are precision parts and require special attention to quality. Our aim is to fulfill the quality promise of “Made in Germany“. With self-developed software for instant price calculation of CNC-machined parts, but also with our quality components, which are used by global customers in various industries.

Our goal is to deliver tangible and strategically relevant added value for companies of all sizes. The easiest way to try our digital solution is to directly use our online calculation for turned and milled parts. Simple, free and right in your browser. You’ve never left delivery issues or cost pressures behind so quickly.