Ordering process for your turned and milled parts

Quotation

and Ordering

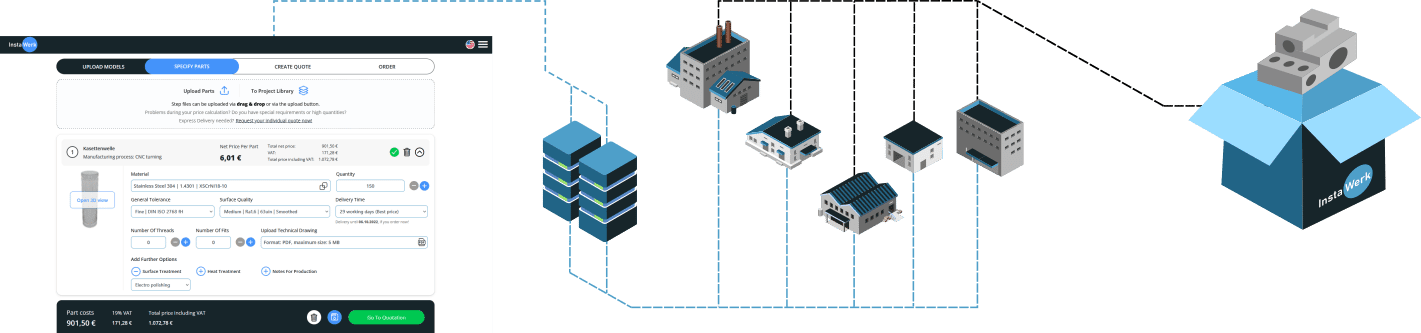

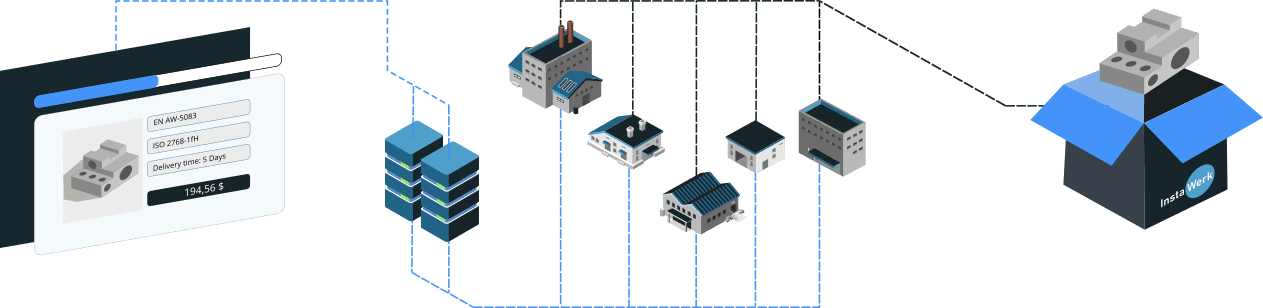

Load your CAD models of your turned and milled parts into our online configurator or send us the parts by e-mail. In the online configurator you can calculate and order your parts immediately or have a written quotation sent to you. For e-mail requests, you will receive your offer back by e-mail in the shortest possible time.

Manufacturing

in our Network

After your order, we bundle your order with other orders and assign the orders to our closed CNC manufacturing network. By bundling orders, you will receive the best conditions and highest quality. In addition, on our CNC-Platform on-time manufacturing capacities are always available.

Quality Control

and Delievery

After completion of CNC manufacturing, your components will be post-processed if necessary, inspected and shipped to you. For urgent orders, express options are available in manufacturing and for shipping. For critical components,

test certificates and initial sample reports can be provided by arrangement.

We offer you three convenient ordering options

for your turned and milled parts

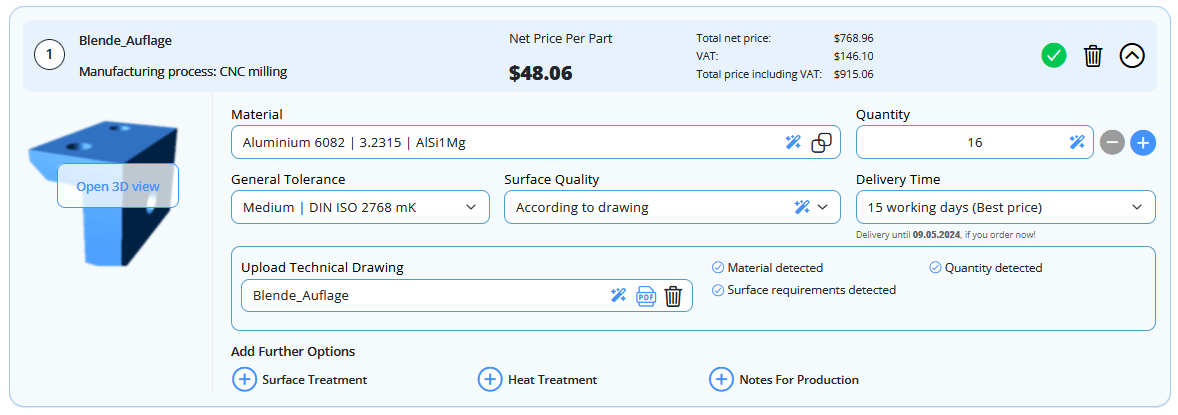

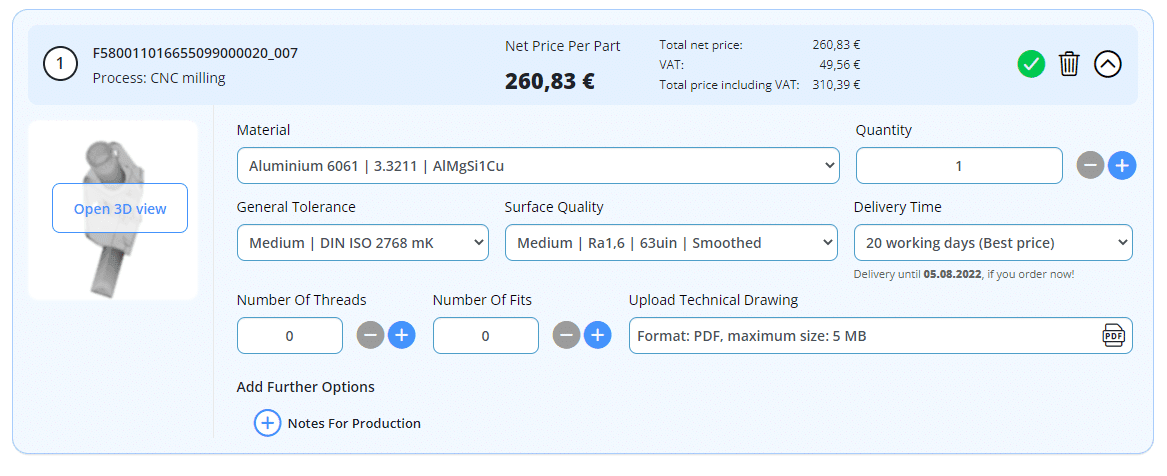

You can order your CNC machining through three channels. The fastest way to order is to use our online calculation for milled and turned parts. Here, all you need to do is upload and specify your CAD model in .step format. Our instant pricing calculates the part cost of your CNC parts for you in just a few seconds. During the ordering process you have the choice: Either order the CNC parts directly at the calculated price or, as a business customer, have a quote sent to your purchasing department by e-mail.

For more complex projects, very short delivery times and larger series, we recommend that you make an inquiry via our contact form. One of our engineers will then be available as your contact person during your project and will prepare an offer with you at the usual top conditions at InstaWerk.

Online Calculation and Ordering

CNC milled parts calculated and ordered in 1 minute with CAD file.

Online Calculation and Quote

Written quote for your purchasing department in just a few clicks.

Individual Agreements

Customized solutions for your CNC production.

Our CNC-Manufacturing Technologies

CNC-Milling

From 3-axis to 5-axis milling: We automatically determine the appropriate process for your components and calculate the corresponding hourly rates directly into your milled parts.

CNC-Turning

Whether pure turned parts or turned/milled parts, we bring precision to your rotationally symmetrical CNC components. We process all machinable materials, from aluminum to titanium.

Eroding

With spark erosion or wire erosion, we can realize dimensionally accurate ablations even in the smallest dimensions. This means that even complex tools or paths can be implemented.

Post treatments

Heat treatments, surface treatments or inscriptions – from anodizing to galvanizing – We offer all common post-treatments – many even directly online.

Why use InstaWerk for the procurement of turned parts & milled parts?

Save Time.

With InstaWerk, both an online calculation with immediate offer and classic mail inquiries are possible. Components can be delivered to you in record time thanks to express options.

You order your CNC parts in 10 clicks and we deliver in record time.

Save Cost.

Cost savings in the procurement of turned parts and milled parts through order bundling, digital ordering processes and an efficient manufacturing network.

On average, you save -20% in component costs and -20% in indirect procurement costs.

German Quality.

In our closed-loop manufacturing network, quality comes first. We continuously audit, monitor and regulate on the basis of thousands and thousands of components. This means that you reliably receive outstanding quality.

Due to our focus on quality, the complaint rate is less than 1%.

Availablity.

Production from quantity 1 to ∞, processing of all machinable materials from aluminum to zinc and comprehensive post-treatments, heat treatments and coatings possible.

Anything elese you need? We will take care of it.

Permanent 100% availability for your production needs.

How does the online calculation

of my turned and milled parts work?

You export your CAD data individually as parts in .step format and simply upload them to the server via our uploader. Our online software checks your parts for features and prepares all data.

Determine the desired material, necessary finishing and delivery date. You will see the price immediately. You can save uploaded parts as projects and call them up again at any time.

You will then receive an order overview. Here you can choose whether you want to order directly or request a quote as a business customer. You can also save on shipping costs by combining shipments or shipping time-critical parts more quickly.

Just add your contact details and delivery address and the CNC production of your components can begin. Congratulations. You are part of a small elite that has taken advantage of digitization.

The digitized CNC Job Shop

About InstaWerk: Turned & Milled Parts, EDM. From Aluminum to Zinc.

InstaWerk is Germany’s leading online manufacturer of turned parts and milled parts. Our simple, digital processes allow us to realize best conditions, convenient ordering and fast deliveries. On the one hand we offer online calculation of your CNC parts in our online store, and on the other hand you can submit classic e-mail requests, which we process in record time. You will receive your e-mail quotations in 24 hours – in complex exceptional cases in up to 48 hours. Offers in the online store are available immediately.

We process and store your data exclusively on professional servers in Germany. Since we also use self-developed calculation software, we can safely exclude data outflows.

The transfer of your data, which is necessary for production, is only carried out to selected CNC contract manufacturers with whom we maintain a close relationship of trust and confidentiality agreements. In addition, you can also conclude a non-disclosure agreement with us as the CNC manufacturer before uploading your data.

You order your turned and milled parts directly from InstaWerk, which means that we, as CNC contract manufacturers, remain your competent contact for your turned and milled parts throughout the entire ordering process.

The procurement of CNC milled parts as prototypes and small series is a long, frustrating and resource-intensive process for companies, research institutes and development departments. If you want to have milled parts manufactured, you’ve come to the right place – whether as CNC prototypes or in series.

Because with InstaWerk as an online manufacturer of milled parts, you always get the best conditions in terms of price, quality and delivery time by bundling orders. This puts an end to the tedious and time-consuming search for a suitable manufacturing partner for your individual turned and milled parts. On average, we undercut competitors’ offers by 19.6% by bundling orders.

We offer business and private customers throughout Germany immediate quotation generation through our online price calculation tool. From the upload of a 3D model, it is thus only a few clicks to order initiation. The upload is done in STEP format. A wide range of materials, tolerance classes, delivery times and surface qualities are available. For more complex inquiries in larger series, special materials or tolerances, we are available to business customers for an individual inquiry. A team of engineers will work with you to develop a competitive quotation.

By focusing on CNC machining, we can offer specialist expertise for your issues, but also meet our manufacturing partners at eye level. Every month our manufacturing capacity grows so that we can offer permanent availability for your orders and also have access to specialized machines for special processes.

You can either order turned parts, milled parts and turned-milled parts in our online store or contact us directly by inquiry. In our online configurator we are currently oriented to the following dimensions:

– CNC milled parts up to a maximum edge length of 1000 mm

– Tolerances according to drawing definition or configuration in the online store

For us, the focus is on customer benefit. We understand that complex designs evolve over years and products need to experience steady market penetration. We therefore offer agility in the procurement of prototypes and small batches, but also successfully support diverse customers in series production through our international manufacturing network. This makes InstaWerk ideal for anyone looking to implement a scalable manufacturing strategy. We will be happy to assist you personally at any time with the planning of more extensive production scales.

In our online calculator you can conveniently select from a variety of materials. For more specialized materials and production according to drawing specifications, please send us an inquiry via our contact form or e-mail. For more information about our materials in the online configurator, see the Materials section.

– Various aluminum alloys

– Steel alloys

– Tool steels

– Stainless steels

– Titanium alloys

– Plastics such as POM, PEEK or PA

For demanding application and environmental conditions, post-treatment is often an option to further increase the usability of the material. Therefore, we already offer in our online store the possibility to choose from various heat treatments (e.g. stress relieving) and surface treatments (e.g. anodizing of aluminum components). You can find more information under post-treatments.

From Start-up to large Corporates

Sourcing CNC precision components in an uncomplicated, cost-effective and fast way convinces many.

German quality is still unbeaten. The innovative ordering process was also straightforward. The conditions regarding delivery time and costs were excellent. This is exactly what we need to get to our strategic R&D goals faster.

R&D Engineer

Automotive OEM

Especially for small series, the ancillary procurement costs often exceed the direct component costs. We are glad to have found a reliable partner in InstaWerk, whose automated processes allow rapid and high-quality procurement.

Head of Procurement

German Robot Manufacturer

For our research work, we often need CNC components, but in small quantities. Through InstaWerk, we were able to procure the most challenging components efficiently and quickly. Many thanks to the team for accelerating our efforts.

Senior Scientist

German Aerospace Center (DLR)

News from the Machining Industry and our CNC platform

Frequently Asked Questions about our Services

At InstaWerk, the customer comes first: That’s why we design our processes with a clear customer focus. Ordering turned and milled parts from InstaWerk is simple, cost-effective and possible with short delivery times. Thanks to our digital processes and a high degree of automation, we streamline ordering processes and can pass on the cost advantage directly to our customers. An important building block for this is our online calculation, which you can use to calculate and order your turned parts and milled parts 24 hours a day.

But the quality of the components must also be right. Therefore, we do not operate an open platform, but a closed manufacturing network, in which we cooperate openly and transparently with our manufacturing partners. Due to our unique order bundling, we can allocate higher order volumes to individual CNC manufacturers and realize excellent conditions due to the higher utilization. In this way, we are able to reconcile low costs for our customers with the highest quality components. After all, we are an important key account for our manufacturers. Even demands for confidentiality of your data can be reliably guaranteed compared to open platforms.

But InstaWerk also provides a digital sales channel for manufacturers, making us a key enabler of digitalization in the manufacturing industry. Compared to other solutions, our intelligent order matching enables manufacturers to receive more orders that are precisely aligned with their manufacturing capacities. In sum, this means for you: best quality at competitive costs.

The cost advantage of InstaWerk is demonstrated by both direct and indirect cost advantages. With the extensive elimination of administrative procedures through process automation, through our international sourcing and the instant quoting of CNC parts in the online store, we save costs massively. We can pass this cost advantage on to our customers. The bundling of individual orders into relevant order sizes for CNC manufacturers also enables us to reduce purchasing costs. You can quickly convince yourself of these direct cost advantages in our online store if you have your milled parts manufactured by us.

But indirect costs also offer companies clear advantages. Fast, digital processes reduce ancillary procurement costs, as competitive prices are also possible in online costing. Customized procurement solutions and connections to ERP systems make largely automated procurement solutions feasible.

A benefit that is difficult to measure, but crucial for many companies, is also the increase in throughput speed within the company. By procuring CNC parts quickly, our customers are on the market faster and can generate relevant sales sooner. In addition, employees are freed from time-consuming administrative tasks. In this way, InstaWerk also contributes to agile development processes and rapid market trials.

We offer both prototypes and series parts. Online calculation is particularly suitable for prototypes and smaller quantities. Here you can use your CAD model to calculate various configurations of your turned and milled parts and order them directly online.

For series parts with larger quantities or milled parts with special alloys, on the other hand, the inquiry via e-mail or contact form is the best option. We will review your data and will be happy to provide you with an offer. Our engineering team also takes care of all in-depth questions for series inquiries.

In our online calculator we offer a large number of different materials. These range from aluminum alloys to titanium and machinable plastics. You can get an impression of our online selection on our materials page. The materials that can be selected in the online calculation are well suited for machining and are usually available quickly and at low cost. This is also your advantage.

If you need other materials for your CNC parts, please send us an individual request. We usually process production requests in 24h, in complex exceptional cases we need a little longer.

For complex CNC components (high quantities, high tolerance requirements, special alloys or similar) you can send us an individual inquiry by e-mail.

For express requests we are your right contact. We have already realized projects with a turnaround time of just under two hours from call to delivery. Under Express delivery of CNC parts you can find out about the process and send us the necessary data.

Your data is in safe hands with us. Multiple security mechanisms ensure a high level of security and confidentiality. Our German server locations with firewalls, SIEM and IDS/IPS technology and ISO 27001 certification provide the hardware basis for the highest data security standards. Since we develop our software completely in-house, we can consistently exclude data outflows compared to SaaS solutions. What ends up on our servers stays on our servers.

For the production of your CNC components, the CAD models and your drawings are shared with the manufacturer in our network. However, we maintain strict non-disclosure agreements with all manufacturing partners, so they are contractually bound to confidentiality. Since we don’t put your manufacturing jobs out to bid, compared to other vendors, but instead award them directly, your data is never exposed to a large network.

Our platform strategy is based on a curated network. Instead of letting the network grow indefinitely on the manufacturing side by opening it up, we rely on a few hand-picked partners that we utilize to the maximum. This makes InstaWerk a key account for many pavers. Compared to open platforms, it would be correspondingly painful for InstaWerk to lose production orders due to a data leak at the manufacturer. This strategic construct protects our customers because our manufacturers work with us on a trust-based, long-term and fair basis instead of just filling capacities in the short term.

Basically, you make this decision yourself through your component and the requirements you choose. Geometric component complexity, delivery time and quality requirements for surface or dimensional accuracy lead to an automated assignment of the production order to a production lot at a CNC manufacturer. The algorithm thus searches for the best possible job shop for your requirements in our network.

Sounds complicated at first, but you won’t even notice it in the ordering process. Simply upload your CNC parts, configure your turned and milled parts and after ordering our software will take care of the rest. In case of queries or coordination efforts, our customer advisors are at your side.

Yes 🙂

We perform all CNC machining processes (turning, milling, eroding, …) and the associated finishing treatments.

This is our little secret 🙂

Especially the online calculation of CNC milled parts is complicated. Automated complexity evaluation, machine allocation, machine cost as well as planning cost calculation are some of the important sub-processes running in the background. But material and semi-finished product costs, fixtures and other manufacturing issues also go into the costing of turned and milled parts.

An important lever, for example, is the extensive process automation, so that we can offer excellent quality, short delivery times and competitive costs as a highly specialized manufacturing platform.

We will always help you. If you have any queries , our customer service representatives will be happy to assist you. You can reach us by phone at 0711 / 26 37 56 02 or by e-mail at support@instawerk.de.

You can get to your written quotation in two ways: Either you upload the CAD data of your parts into our online calculation tool and have a commercial quotation generated in the order process or you send us your parts with your drawings to support@instawerk.de and we will prepare a competitive quotation for you in a short time.

Needless to say. With us, you get CNC production and any downstream steps from a single source. Heat treatments such as hardening, surface treatments such as burnishing or anodizing, but also coatings (chrome plating, galvanizing, etc.) or markings are available to you both in our online tool and via e-mail inquiry.

Instead of buying their own machines, maintaining them and hiring staff for manufacturing, so-called on-demand services offer the advantage of a more flexible, cost-effective and fail-safe solution. In addition, many companies recognize the value in simple, digitized processes and the ability to focus on your core business rather than chasing day-to-day manufacturing issues. We have written a separate article on this, which we would like to recommend to interested readers.

For start-ups, research institutes and other innovation drivers, the value of InstaWerk lies primarily in being able to order fast, cost-effective and top-quality turned and milled parts conveniently and without complications. This allows even small teams to successfully develop innovations and bring them to market.

But larger companies also see the advantage of InstaWerk: In addition to unbeatable conditions, we can score points with digital processes, fast and uncomplicated procurement solutions and outstanding quality. Thus, InstaWerk is becoming a preferred solution in strategic procurement for more and more larger companies.

Your Direct Contact for all CNC Orders

We are here for you.

Do you have questions about the ordering process, need materials or surface treatments that are not offered via our online mask?

Drop an E-mail

support@instawerk.de

Call us.

+49 711 2637 56 02

Our materials by Order Volume

Low density, efficient machinability and manageable costs are the hallmarks of aluminum turned and milled parts.

High resistance to various media with high load capacity make stainless steel CNC parts all-round problem solvers.

Extensive post-treatments make steel an all-rounder for mechanical engineering.

With our range of titanium, various plastics and other materials, no wishes remain unfulfilled.

Find out more about our

materials for CNC-manufacturing.