4,87

What our customers say:

“Quality is very good. Really satisfied with the customer service.”

Wide range of different materials for CNC machining:

Order your CNC parts online:

Many Materials online – and all others on request

The selection of the right material can be decisive for the success or failure of an engineering design. At the same time, the variety of available materials is hard to keep track of. To help you select the right materials for your turned and milled parts, we have compiled an overview of common materials below.

At InstaWerk, we have decided to offer common materials online and to reduce the variety. This allows us to offer the best conditions for widely available materials, while at the same time responding to special material requirements via individual inquiry options.

Aluminium Alloys

All other aluminium alloys available

on request.

AlMg4,5Mn – EN AW-5083 (Peraluminium) – 3.3547

Density 2.8 kg/dm³

AlMgSi1 – EN AW-6082 (Anticorodal) – 3.2315

Density 2.8 kg/dm³

AlZnMgCu1,5 – EN AW-7075 (Ergal) – 3.4365

Density 2.8 kg/dm³

AlMg1SiCu – EN AW-6061 (Peraluminium) – 3.3211

Density 2.8 kg/dm³

Steel and Stainless Steel Alloys

All other alloys are

available on request.

Steel A36 – S235JR – St 37-2 – 1.0038

Density 7.9 kg/dm3

Steel AISI 1024 – S355J2+N – ST 52-3 – 1.0570

Density 7.9 kg/dm3

Steel 1045 C45 Steel- AISI – 1.0503

Density 7.9 kg/dm3

Steel AISI 5115 – 16MnCr5 – – EC80 – 1.7131

Density 7.8 kg/dm3

X5CrNi18-10 – Stainless Steel V2A – AISI 304 – 1.4301

Density 7.9 kg/dm3

X2CrNiMo17-12-2 – Stainless Steel V4A – AISI 316 – 1.4401

Density 7.9 kg/dm3

Tooling Steel P20 40CrMnNiMo8-6-4 – MCMS – 1.2312

Density 7.8 kg/dm3

Titanium Alloys available Online

All other alloys are

available on request.

Titanium Grad 2 “Ti 2” – 3.7035

Density 4.5 kg/dm³

Available plastics in the online configurator

All other polymers are

available on request.

Polytetrafluorethylene (PTFE) – Teflon®

Density 2.2 kg/dm³

Polyoxymethylen (POM-C) – Delrin®

Density 1.4 kg/dm³

Polyetheretherketone (PEEK)

Density 1.3 kg/dm³

CNC-Manufacturing

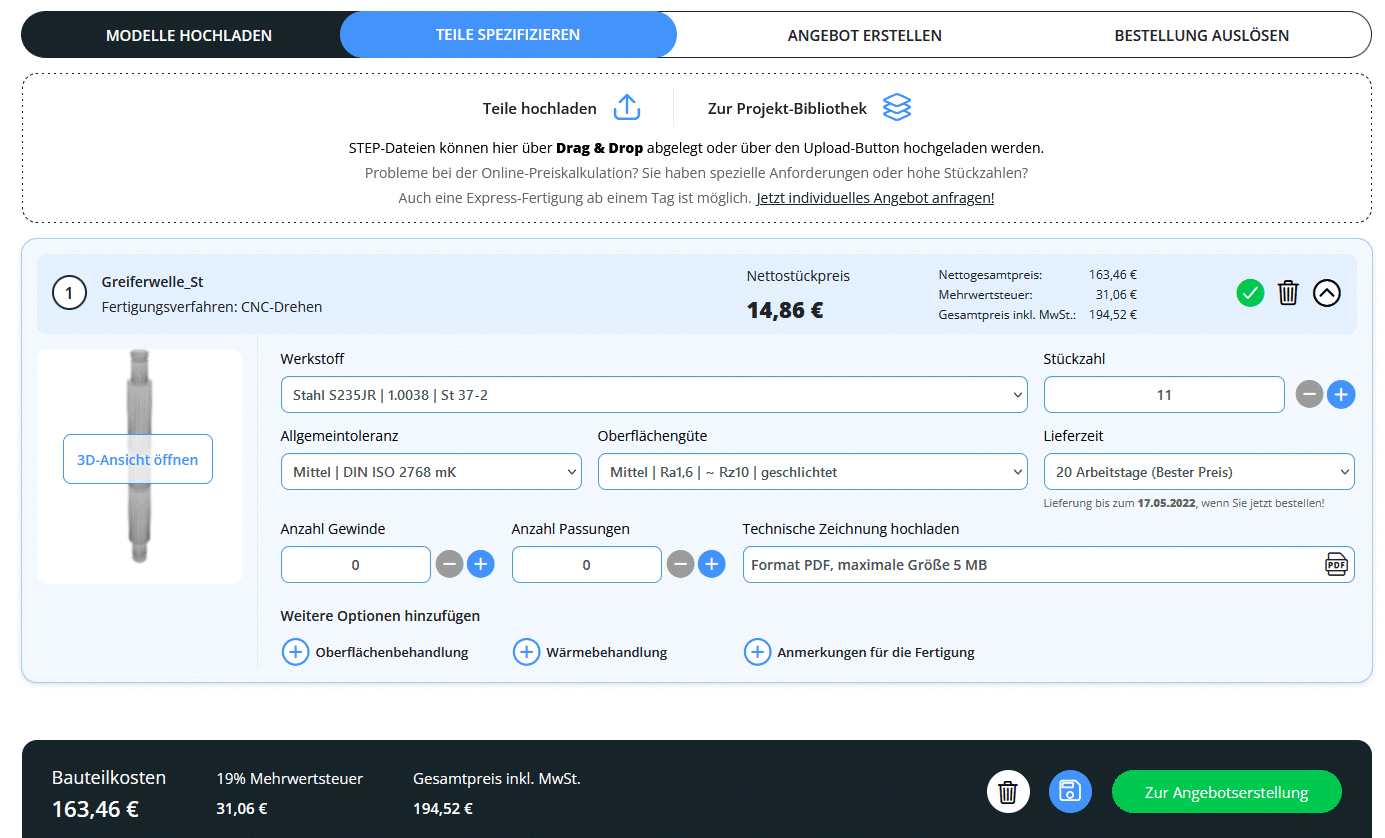

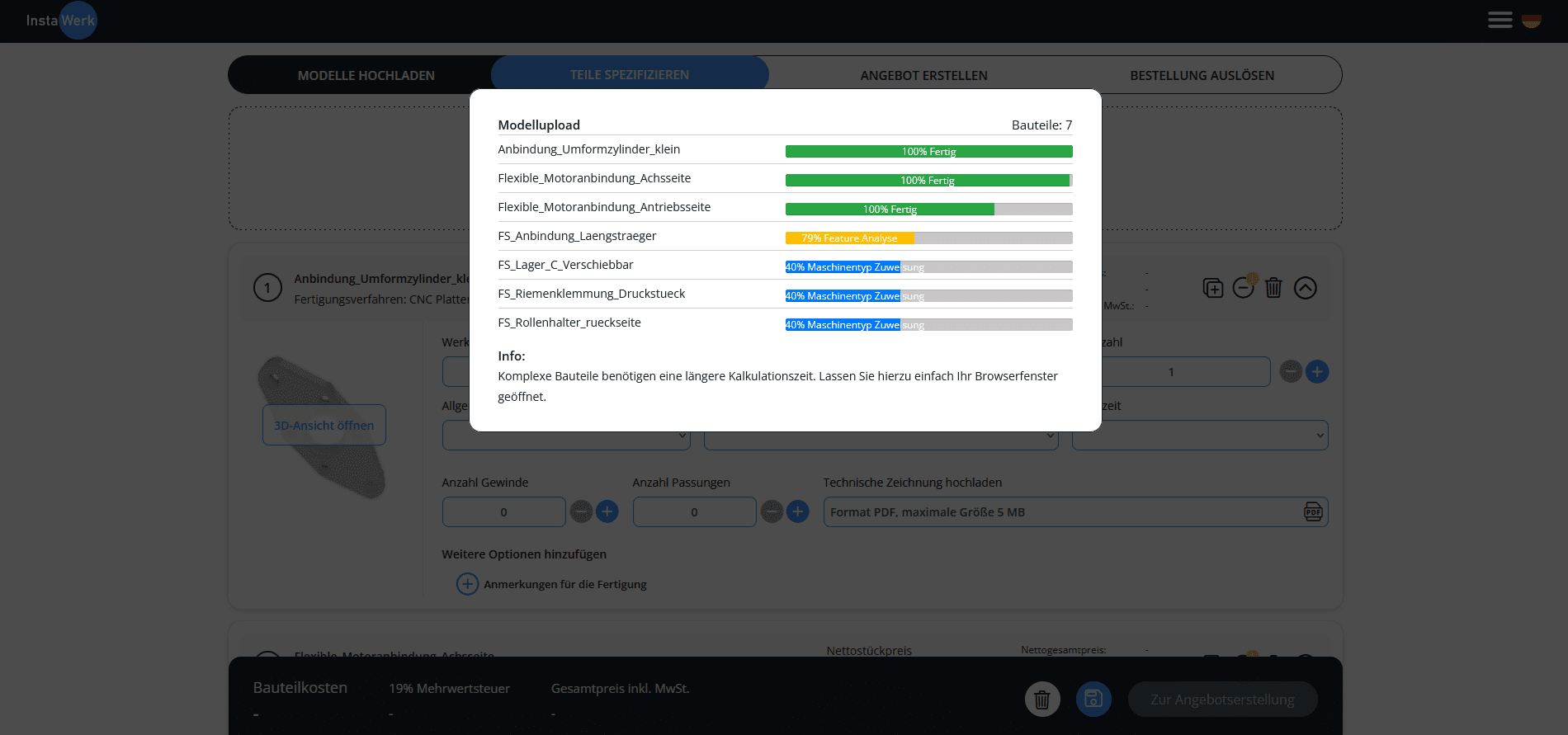

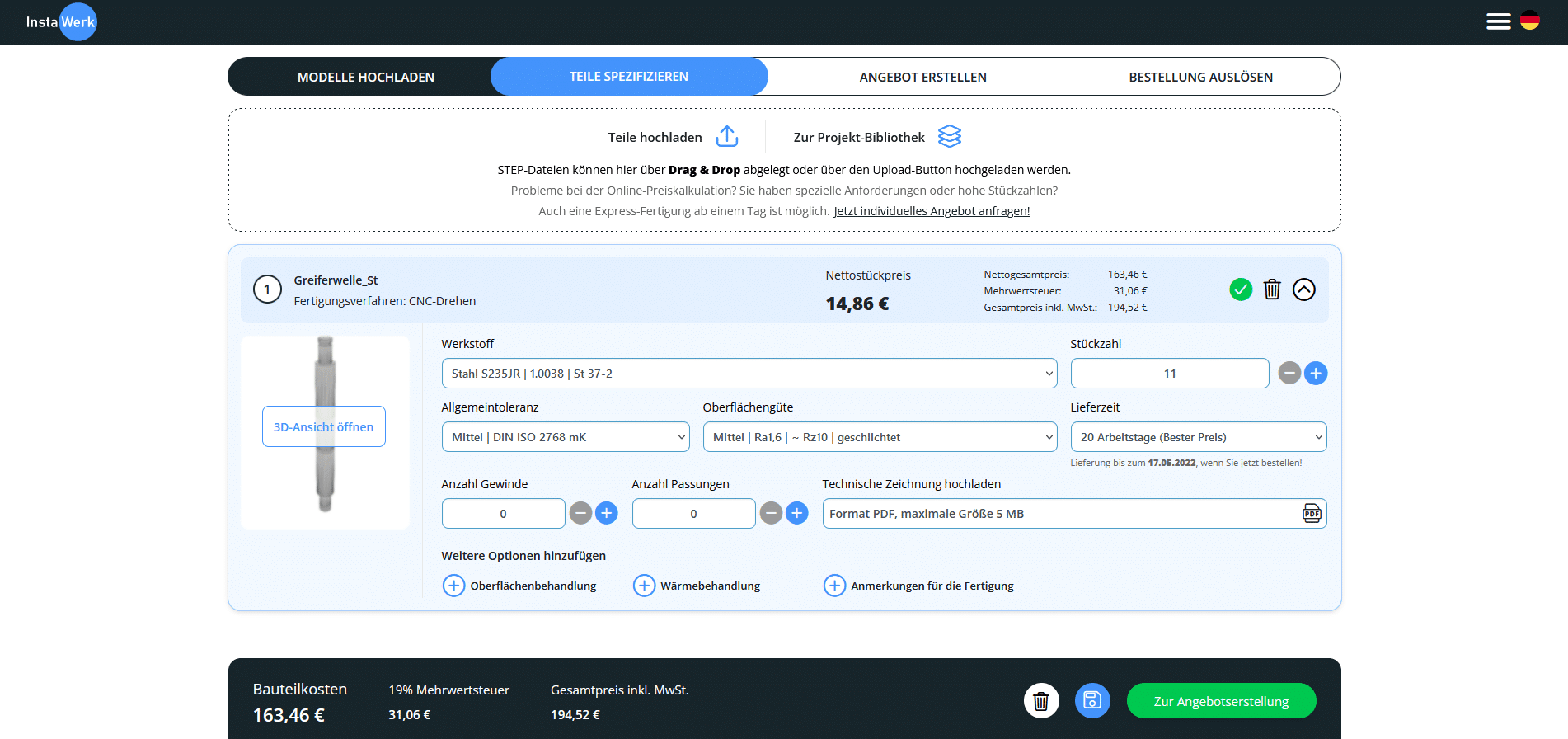

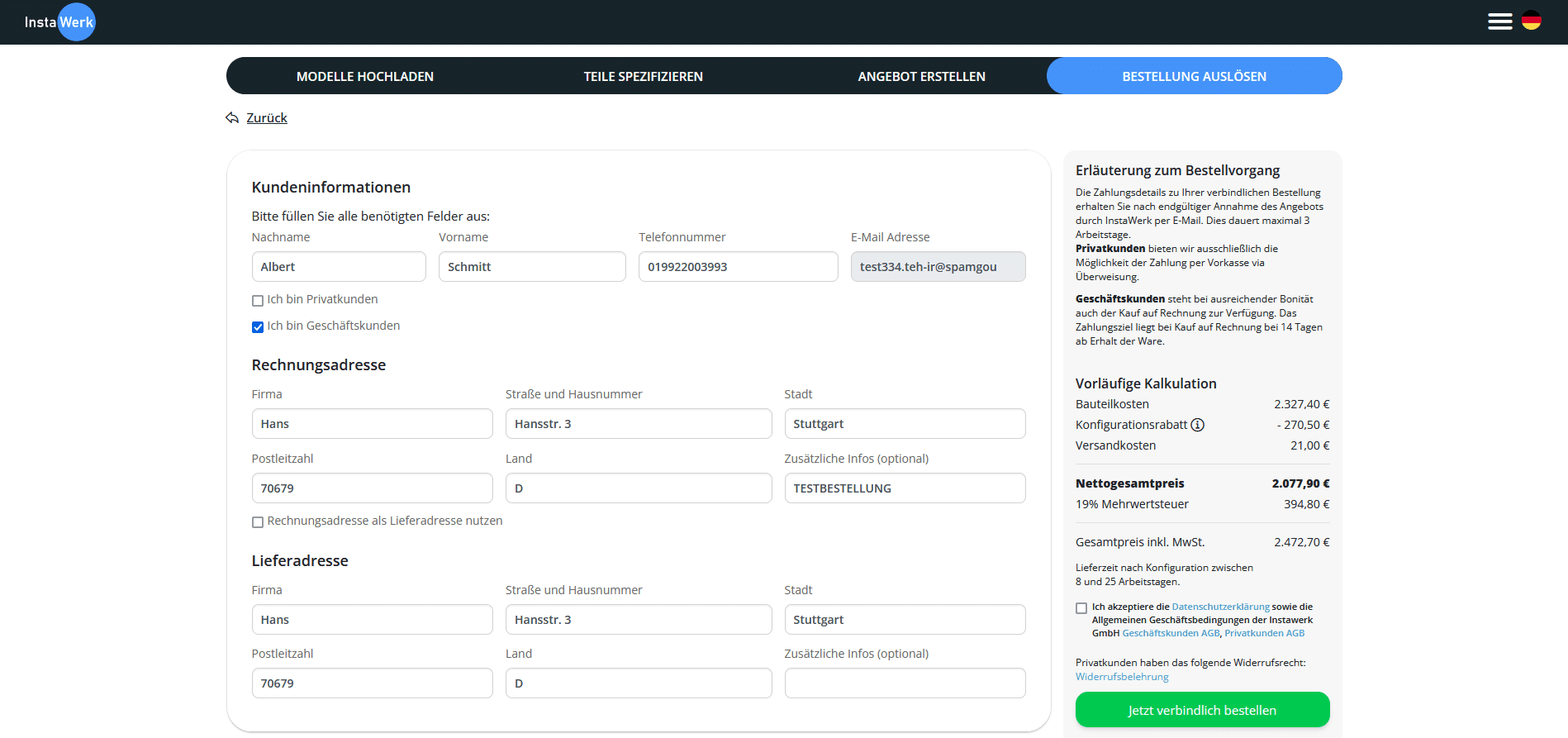

Instant Quoting

The fast online ordering via our online calculator is suitable for all those who want to have turned parts and milled parts manufactured quickly, conveniently and cost-effectively.

1. Upload CAD files

2. Configure parts

3. Order. Done.

Email Request

If you have larger quantities, high tolerance requirements or need special materials, you are better off with an individual inquiry. Simply upload model data here.